Features

We provide "X-ray CT system" with high functionality, high performance, and high convenience.

We can develop and provide X-ray CT system and scan software based on customer feedback, so we can propose the most efficient X-ray CT system suited to the sample.

Do you have any issues like this?

- Want to check if there are any foreign matters in the package [Food company]

- Want to check the distribution of the drug inside the capsule [Pharmaceutical company]

- Want to scan mouce using X-ray CT scan which puts less stress on the body [Research institutes]

-

Customize the CT system according to the sample, achieving excellent quality and high cost performance.

-

Develop and provide X-ray CT system and scan software meeted to customer needs and samples.

-

Based on our experience in X-ray CT system, we can propose the optimal scan protocols according to the customer's requests, and we can also undertake X-ray inspection contract service.

01Customize the X-ray CT system according to the sample, achieving excellent quality and high cost performance.

Why is it chosen?

We also propose scan and analysis methods such as dimensional measurement, void analysis, line inspection, and soft tissue staining.

We have achieved low prices by using main components that are optimally configured to meet user needs.

02We develop and provide X-ray CT system and scanning software meeted to customer needs and samples.

We provide "X-ray CT sytem" meeted to customer needs.

We develop and provide X-ray CT system and scanning software meeted to customer needs and samples.

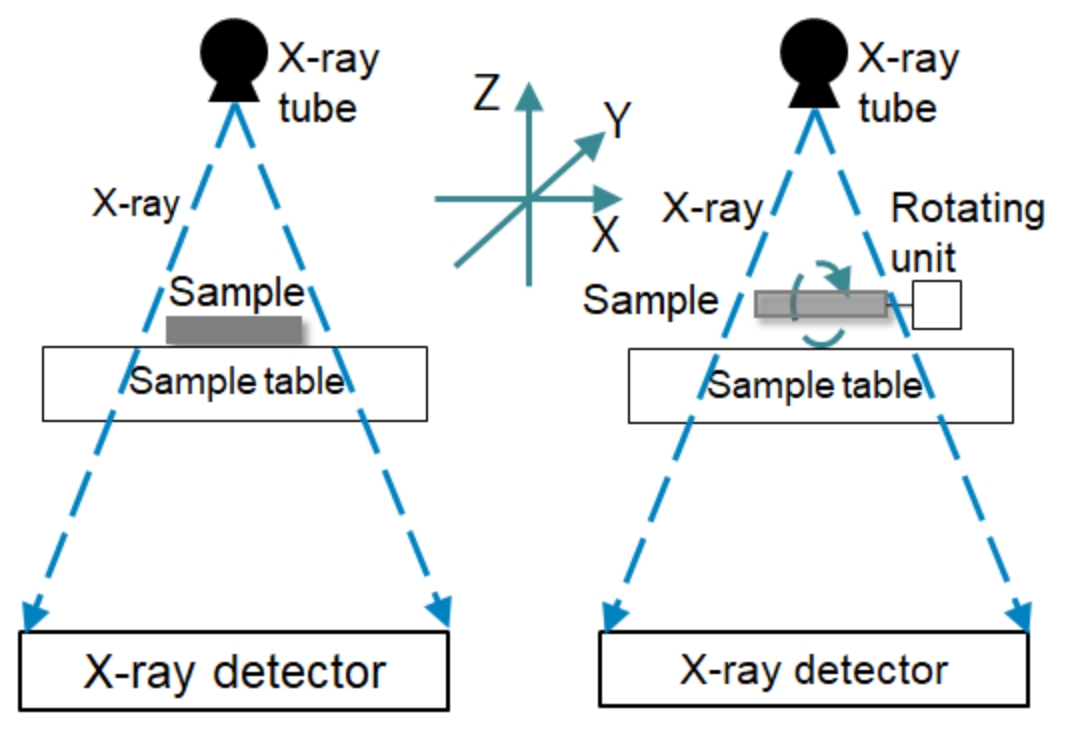

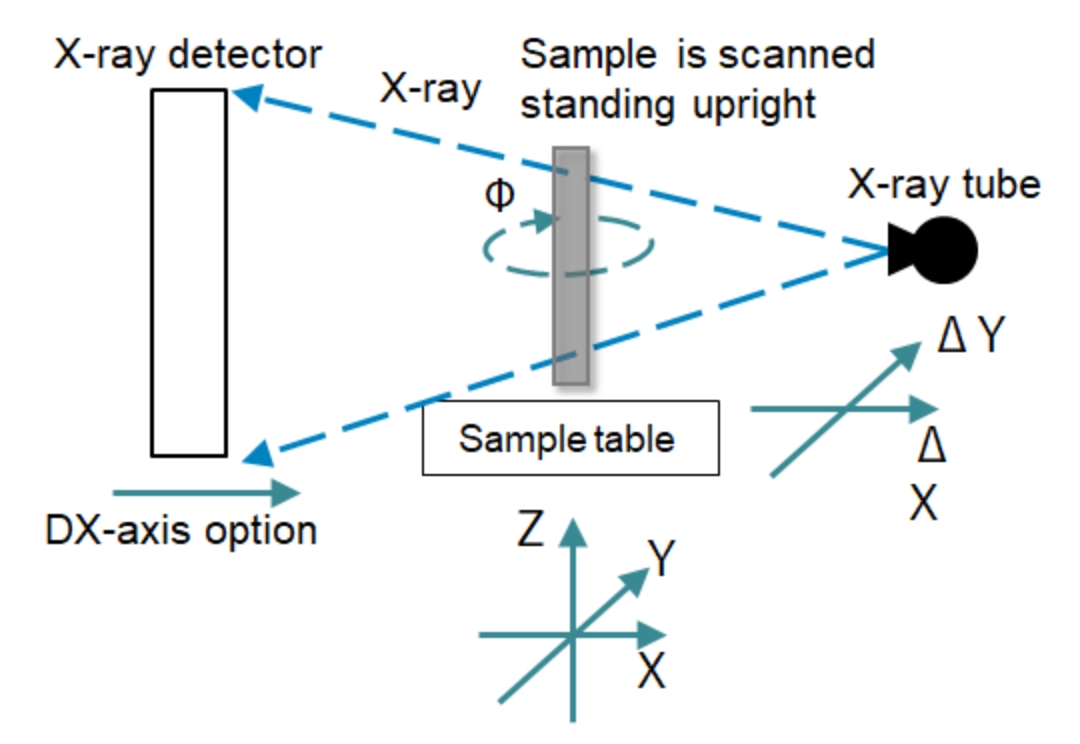

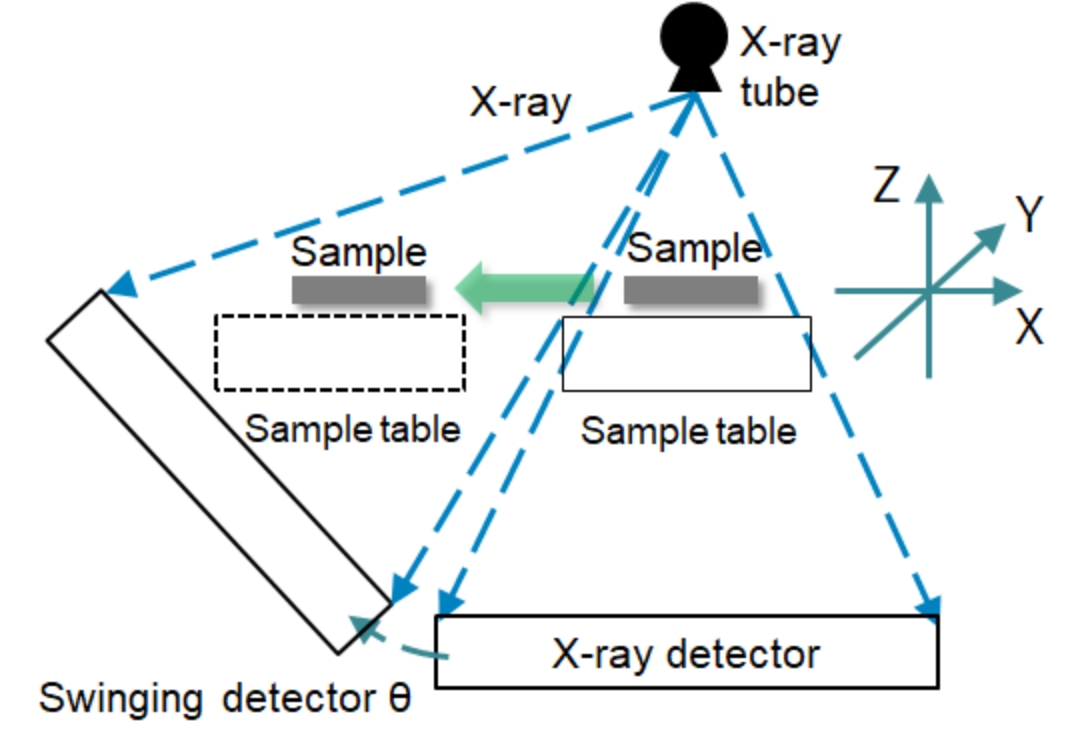

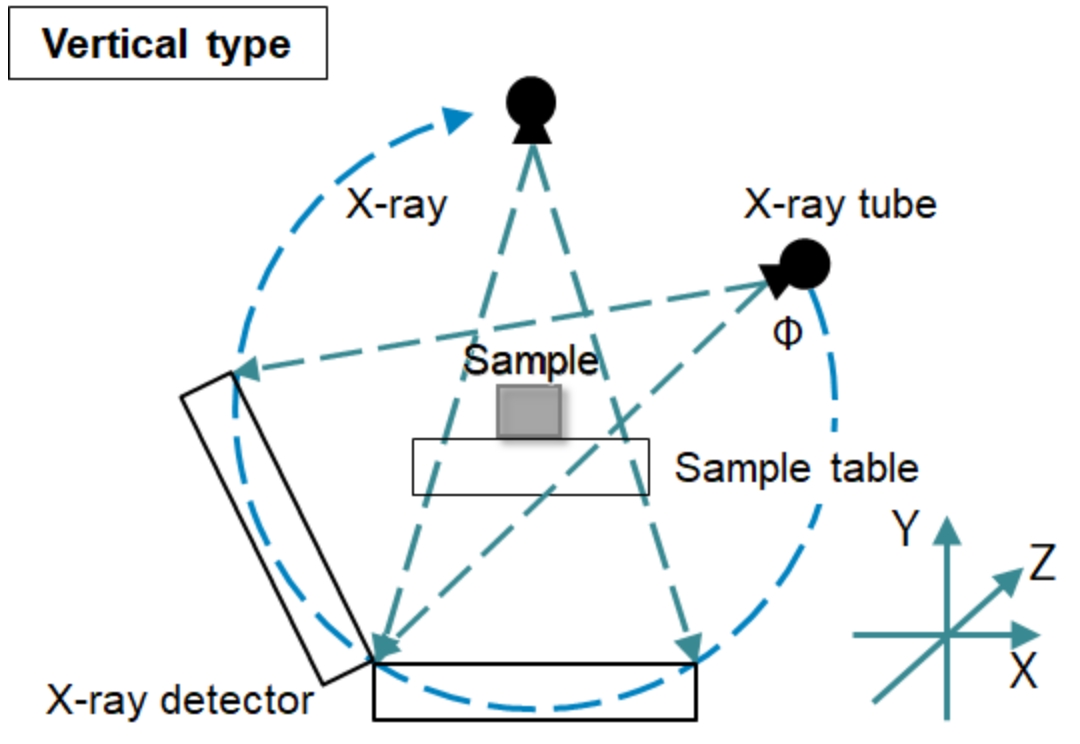

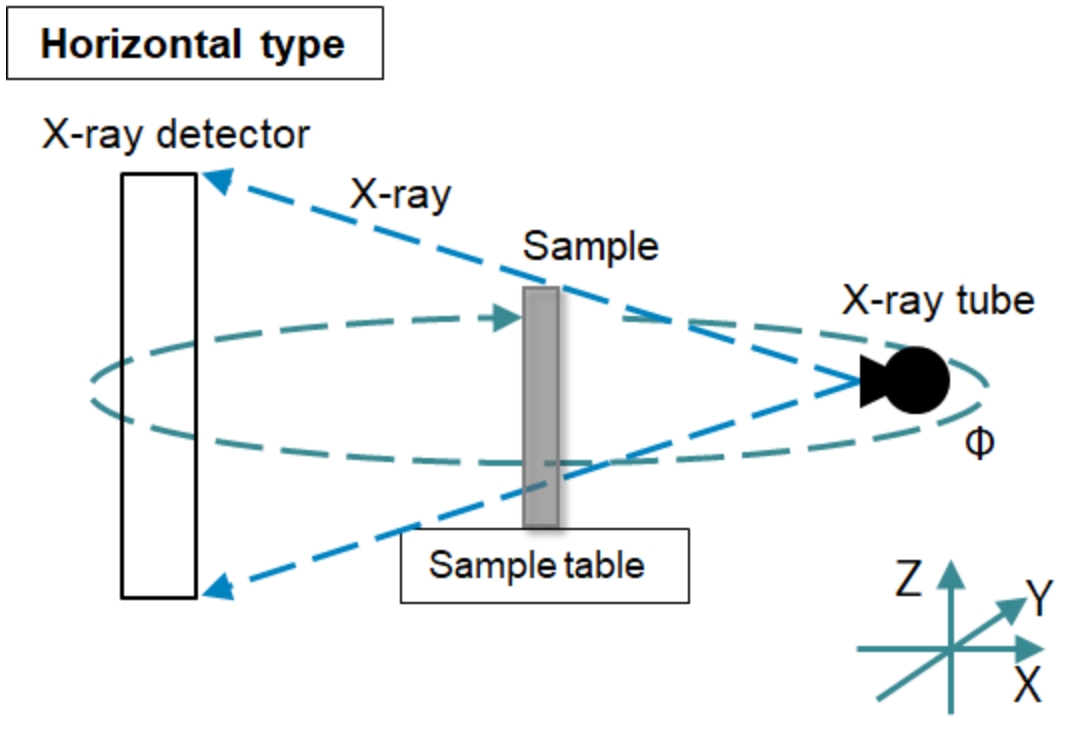

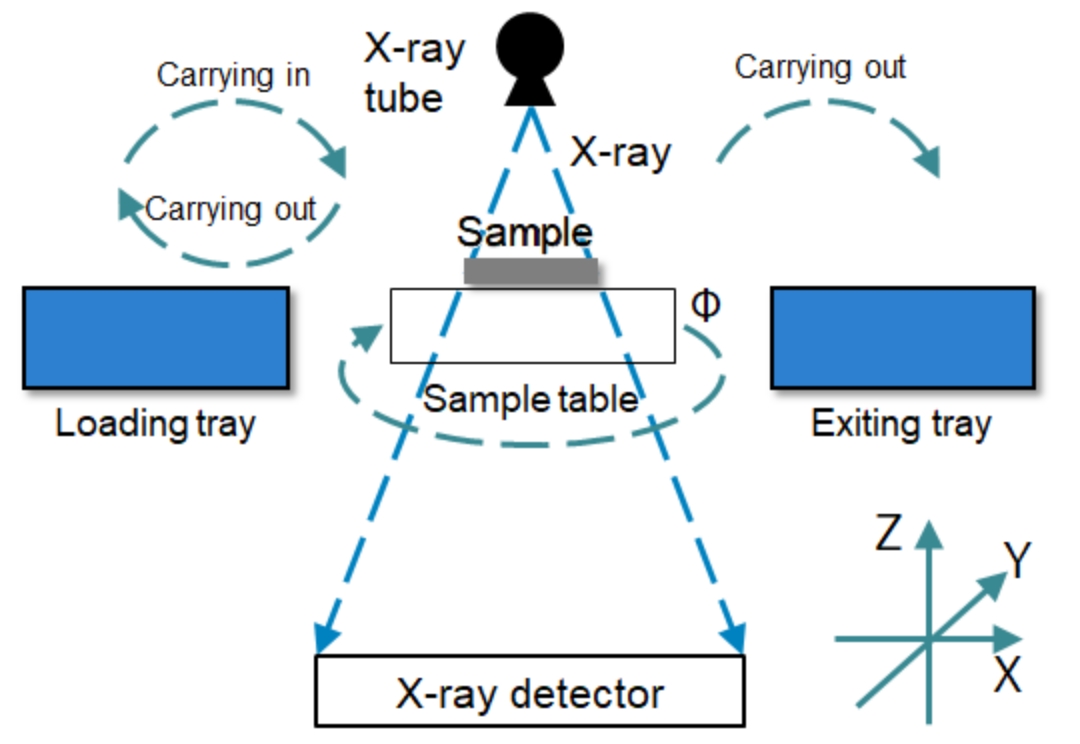

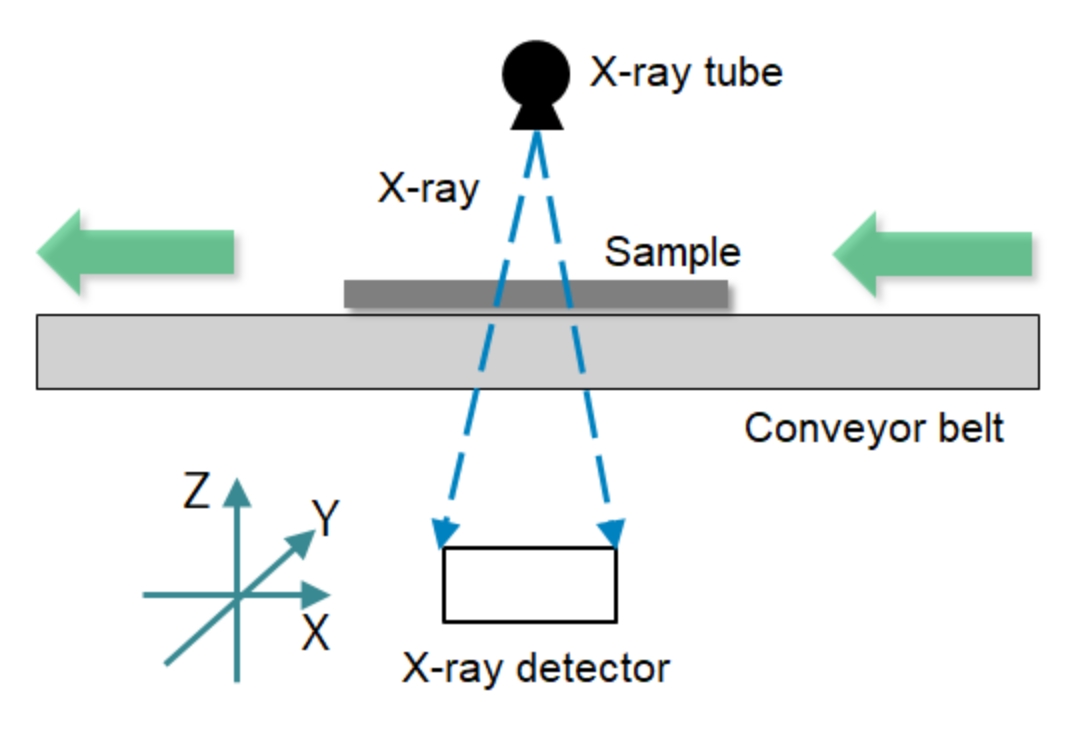

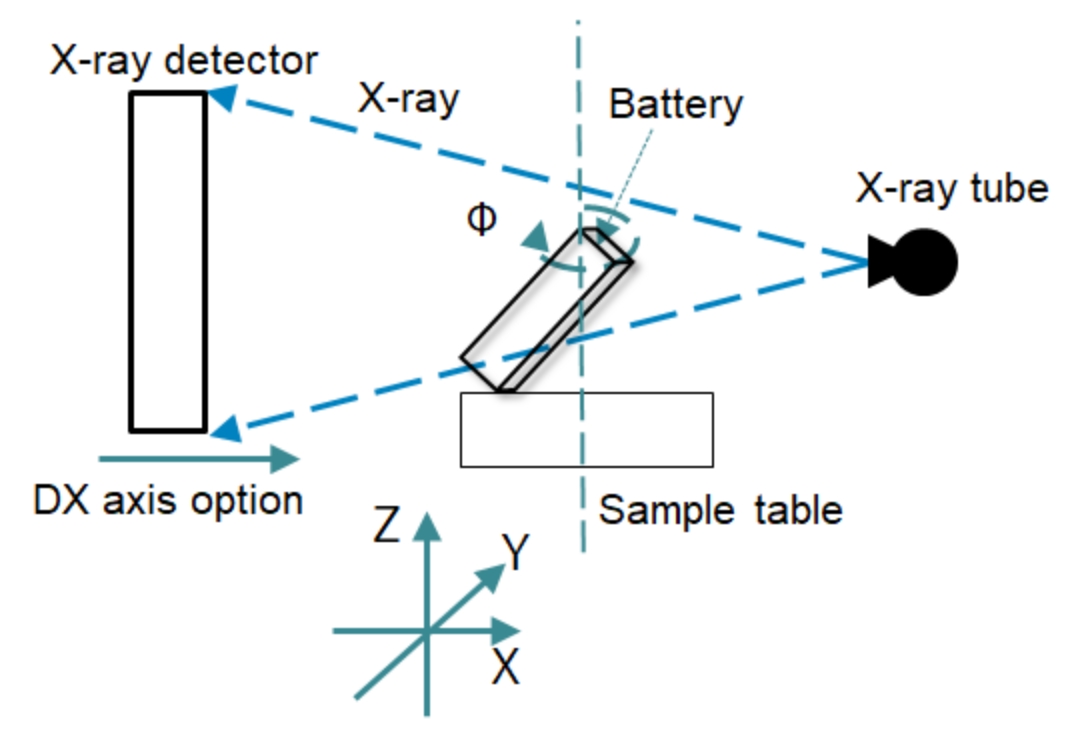

We can propose the effective combinations of X-ray tubes and X-ray detectors, efficient X-ray CT system, scanning modes, and image reconstructions meeted to the sample.

X-ray fluoroscopic system is also possible.

X-ray CT scan

An X-ray scan (simple X-ray scan) image expresses the amount of X-rays transmitted by irradiating the object as the grayscale image.

Since it is a two-dimensional image in which all the information in the thickness direction is reprojected onto a plane, the thickness information cannot be expressed.

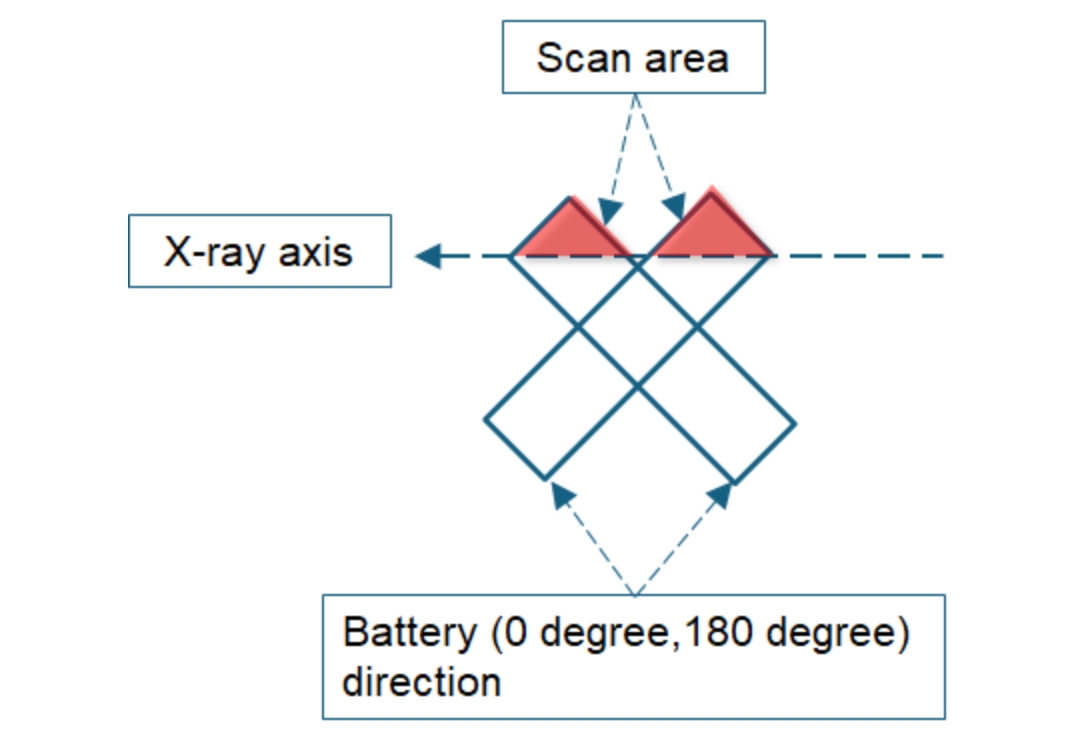

On the other hand, with X-ray CT images, it is possible to obtain 3D internal information by reconstructing 3D volume data through reconstruction processing of fluoroscopic images irradiated by 360 degrees direction's X-ray data of the inspection target.

Features of X-ray CT scan

- The inside of the sample can be visualized and observed in 3D with non-destructive manner.

- It is possible to extract defects such as foreign matters, voids, and cracks, and measure their area, volume, and position in 3D.

- 3D dimension measurement enables the comparison with design values and quantification of wear, deterioration, etc.

- Visually easy-to-understand images and videos can be created from the data of the scanned object.

- Can also be used as STL data for 3D printers.

- Product quality control is possible by using it for sampling inspections and in-line inspections.

(for lithium-ion battery stacking / winding misalignment inspection) 1

(for lithium-ion battery stacking / winding misalignment inspection) 2

03Based on our experience of X-ray system, we can propose the optimal scan protocols according to your requests, and we can also undertake X-ray inspection contract service.

The following is the examples of the industries, samples and purposes of our customers.

For the details, please contact us via the inquiry form or by phone.

*If the table is not visible, please scroll left and right.

| Industry | Target sample | Photography/analysis purpose | |

|---|---|---|---|

| Food/Beverages | Food materials (meat, vegetables, fish, grains, fruits, etc.) Processed food |

Internal state observation Observation of the condition inside the package Foreign object identification |

|

| Paper and textile industry | Materials Processed goods |

Structural analysis | |

| Pharmaceuticals Cosmetics |

Tablet Medical equipment Package Container Cosmetics (lipstick, foundation, mascara, etc.) |

Analysis of voids and cracks Observation of package contents Container leak test Observation of drug structure Failure analysis Product sampling inspection |

|

| Other chemical industry |

plastics ceramic rubber glass etc. |

Analysis of voids and cracks Identification of contaminated foreign objects Orientation analysis of fiber-containing material fibers |

|

| Electrical appliance manufacturing |

Electrolytic capacitor inductance small motor large motor compressor evaporator |

Internal state observation Product sampling inspection Failure analysis |

|

| Optical instrument manufacturing | portable camera Optical system OHP parts for transportation machinery |

Checking the assembly status Dimension measurement Product sampling inspection Failure analysis |

|

|

Telecommunications mechanical parts electronic components electronic device Electronic circuit manufacturing |

battery capacitor filter Crystal oscillator light emitting diode connector micro motor Printed circuit boards etc. |

Evaluation of developed products Sampling inspection 100% inspection Failure analysis Automatic solder void rate determination Battery winding inspection |

|

| Universities and research institutes | Department of Biology in vitro |

Small animal hard tissue (bones/teeth) Small animal soft tissue (by staining) |

Internal observation and structural analysis |

| Fossil |

bone animal insect plant |

internal observation structural analysis |

|

FAQ & CT Column

FAQ: Frequently asked questions

Is the dedicated X-ray scan room needed to install the X-ray inspection equipment?

Since the industrial X-ray inspection equipment includes the X-ray shield box and does not leak X-rays outside the shield box, so the dedicated X-ray scan room is not necessary.

Is any notifications needed to be submitted when installing the X-ray inspection equipment?

In order to introduce the industrial X-rayinspection equipment, the notification is required. Please contact us for details.

Does the operator need any special qualifications?

Customers do not need any special qualifications to use our X-ray inspection equipment.

Please feel free to contact us with any requests or questions regarding product information or quotations.

(Weekdays 9:00-17:00)